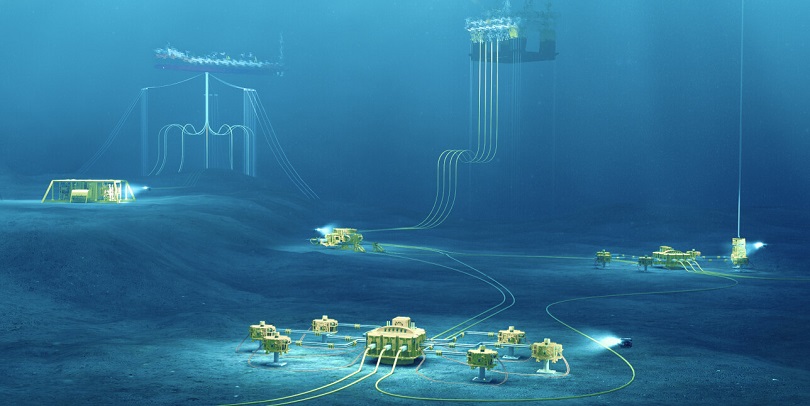

Subsea umbilicals play a crucial role in the offshore oil and gas industry, serving as lifelines that connect the surface facilities to the subsea wellheads. These complex systems are integral to the success of underwater exploration and production activities. With this occasion, we’ll delve into the composition, functions, types, and installation processes of subsea offshore umbilicals.

Subsea Umbilicals

Composition and Materials:

Subsea umbilicals are intricate bundles of tubes, hoses, and cables that transport various substances, such as hydraulic fluid, electrical power, and chemical injection fluids, between the surface and the seabed. These umbilicals are engineered with a combination of materials to withstand harsh subsea conditions, including corrosion, high pressure, and low temperatures.

Typically, subsea umbilicals consist of a steel or composite strength member for mechanical integrity, surrounded by layers of thermoplastic or thermosetting materials to provide protection against environmental factors. Copper or aluminum conductors may be incorporated for transmitting electrical power, while hydraulic hoses enable the transfer of hydraulic fluid to control subsea equipment.

Scope and Functions:

The primary purpose of subsea umbilicals is to facilitate the control and monitoring of subsea production systems. They enable the transmission of power and signals required to operate subsea valves, sensors, and other equipment. Additionally, chemical injection lines within the umbilicals allow for the delivery of chemicals to the wellhead for purposes such as hydrate inhibition and corrosion control.

These umbilicals also serve as a means for transmitting data from subsea sensors to the surface, providing crucial information about well conditions, flow rates, and overall system performance. In essence, subsea umbilicals are the vital link that empowers engineers and operators to remotely manage and optimize offshore production.

Types of Subsea Umbilicals:

Subsea umbilicals come in various configurations to meet specific project requirements. Some common types include hydraulic umbilicals, electrical umbilicals, and integrated umbilicals that combine both functions. The choice of umbilical type depends on factors such as water depth, well complexity, and the need for additional functionalities like chemical injection or fiber optics for data transmission.

Each type is tailored to address the unique challenges posed by the subsea environment, ensuring reliable and efficient operation throughout the lifecycle of the offshore field.

Installation Process:

Installing subsea umbilicals involves a meticulous and often challenging process. Typically, the installation is carried out using specialized vessels equipped with a dynamic positioning system to maintain precise positioning over the subsea infrastructure.

The installation process begins with the deployment of the umbilical from the vessel to the seabed by the use of the VLS (Vertical lay System). Subsea remotely operated vehicles (ROVs) are often employed to assist in the precise placement and connection of the umbilical to the subsea infrastructure. The umbilical is then secured to the seabed using clamps or other anchoring systems.

Careful planning, coordination, and adherence to safety protocols are essential during the installation process to ensure the successful integration of subsea umbilicals into the offshore production system.

Subsea offshore umbilicals are indispensable components of modern offshore oil and gas operations. As technological advancements continue to push the boundaries of deep-sea exploration, the role of subsea umbilicals becomes increasingly critical in enabling efficient and remote control of subsea production systems.

Understanding the composition, functions, types, and installation processes of subsea umbilicals is crucial for industry professionals involved in offshore exploration and production. These lifelines beneath the waves exemplify the convergence of engineering expertise and innovation in the pursuit of extracting energy resources from the depths of our oceans.

If you want to know more about offshore specific vessels, follow the link for the largest cable laying vessels.