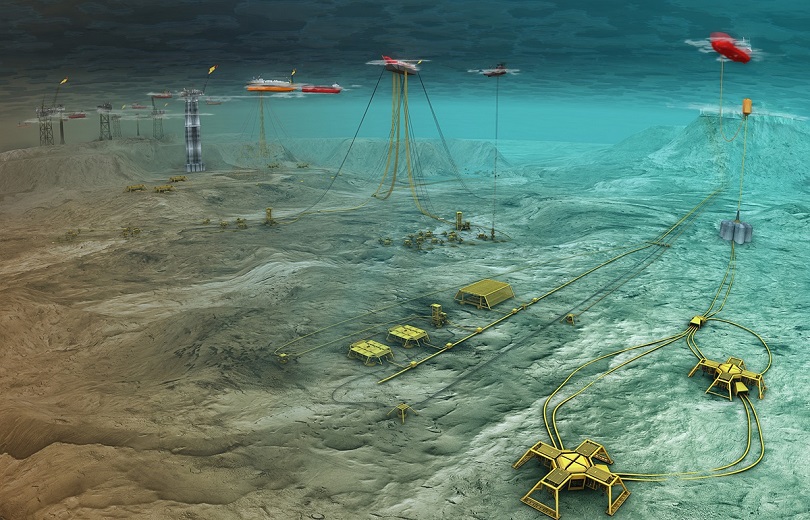

Oil and Gas offshore construction sector plays a crucial role in the energy industry, enabling the extraction of oil and gas from beneath the seabed. Central to this process is the pipe lay operation, which involves the installation of pipelines that connect offshore wells to production facilities offshore and onshore. Below we will highlight the main steps in the pipe lay process in offshore construction and delves into its scope, methods, and significance in the global energy sector.

1.Offshore Pipe Lay:

The scope of the pipe lay process in offshore construction is vast and multi-faceted. It encompasses various activities, including:

Pre-Engineering Survey: Before the pipe lay commences, a thorough engineering survey is conducted to assess the seabed conditions, identify potential obstacles, and plan the best route for the pipeline installation. This phase is crucial to ensure the pipeline’s integrity and minimize environmental impacts.

Pipe Fabrication: The pipes used in offshore construction are typically large-diameter steel pipes that are fabricated onshore. These pipes are specifically designed to withstand the harsh marine environment and the stresses encountered during installation and operation.

Transportation: Once fabricated, the pipes are transported to the offshore location using specialized vessels, such as pipe-laying barges or pipe-laying vessels. These vessels are equipped with advanced technology to handle the heavy load of pipes and maneuver them into position.

Pipe Installation: The actual pipe lay process involves lowering the pipes from the vessel onto the seabed. Various techniques are used for this purpose, including S-lay, J-lay, and towed bundle methods. The choice of method depends on factors like water depth, seabed conditions, and the length of the pipeline.

2. The Pipe Lay Process:

S-lay Method: In the S-lay method, the pipe-laying vessel moves forward while the pipe is continuously fed from the stern. As the vessel advances, the pipe gradually forms an “S” shape before reaching the seabed. The curvature is essential to accommodate the stresses during installation. Once the pipe is laid on the seabed, it is secured and welded to the previous section.

J-lay Method: The J-lay method is primarily used in deep-water applications. In this approach, the pipe is suspended vertically from the vessel’s J-lay tower. As the vessel moves forward, the pipe is lowered to the seabed in a controlled manner, forming a gentle curve rather than an “S” shape. This method is well-suited for pipelines in ultra-deep-water regions.

Towed Bundle Method: The towed bundle method involves the fabrication of a bundle of pipes onshore, which is then towed to the offshore location by a tugboat. Once at the site, the bundle is submerged to the seabed, and individual pipes are offloaded and connected to create the pipeline.

3. Importance in the Energy Sector:

The pipe lay process is a critical aspect of offshore construction and has significant implications for the energy sector:

Enhanced Production: Efficient pipeline installation enables timely connection of offshore wells to onshore facilities, facilitating the smooth flow of hydrocarbons and enhancing overall production.

Cost-Effectiveness: With advances in technology and methodologies, the pipe lay process has become more streamlined and cost-effective, optimizing project economics.

Environmental Impact: Proper planning and execution of the pipe lay process can minimize environmental impacts, preserving marine ecosystems and ensuring sustainable operations.

The pipe lay process in offshore construction is a complex and vital operation that connects offshore wells to onshore production facilities. With careful planning, innovative technology, increased focus on safety, and skilled engineering, this process contributes significantly to the growth and success of the global energy sector. As the demand for oil and gas continues to rise, the pipe lay process will remain at the forefront of offshore construction, enabling the safe and efficient transportation of hydrocarbons from the seabed to consumers worldwide

Comments

3 responses to “Offshore Construction: Pipe Lay Processes”

Knowledge sharing

The submarine project, Laying cable, Work Procedure System (WPS)

Between

Offshore Construction Pipe Lay Process

Please sharing information both

Thanks for sharing

Best regards

Bancha Yathip

http://Www.Gunkul.com

Hi Bancha,

What is your request, your message is not clear to me? How can I help you?

[…] Pipe Tensioners: These are hydraulic systems designed to apply tension to the pipe as being laid. The tension ensures that the pipe remains straight and properly aligned during installation. It […]