In the vast universe of oil and gas exploration, safety is paramount. One vital component ensuring the safety of high-pressure drilling operations is the Blowout Preventer (BOP). In this article I will take you for walk into the key aspects of BOPs, their main components, and their key role in safeguarding operations.

What is a High-Pressure Blowout Preventer (BOP)?

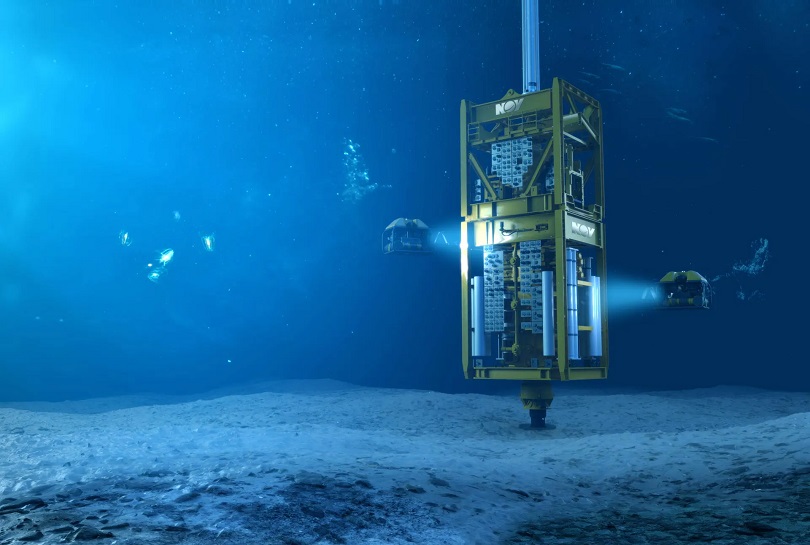

A Blowout Preventer, frequently known as a BOP, is a critical safety device used in high-pressure drilling operations, specifically in the oil and gas industry. It serves as the last line of defense against uncontrolled releases of oil or gas from a well, commonly referred to as a blowout. BOPs play a vital role in preventing environmental disasters, protecting human lives, and safeguarding valuable resources and even the integrity of the drilling vessel.

Main Components of a Blowout Preventer:

Annular BOP:

The annular BOP is a flexible rubber-like component that forms a seal around the drill pipe. It is versatile and can adapt to variations in pipe sizes.

Ram-Type BOPs:

Ram-type BOPs consist of hydraulically operated steel rams that can be closed around the drill pipe to provide a reliable seal. There are two main types: blind rams, which completely close the wellbore, and pipe rams, which seal around the drill pipe.

Control System:

The control system is the brain of the BOP, overseeing the hydraulic functions that operate the various components. It allows for remote and manual control, enabling swift responses to emergency situations.

Accumulator Unit:

An accumulator unit stores hydraulic fluid under pressure, ensuring a quick and efficient response when activating the BOP. This rapid response is crucial in emergency situations to prevent a blowout.

What is a Blowout Preventer Used For?

BOPs are utilized in drilling operations to control the wellbore high-pressure and prevent the uncontrolled release of hydrocarbons. They are deployed during various phases of drilling, completion, and well intervention. The primary functions of BOPs include:

Well Control:

BOPs maintain control over the well by sealing the wellbore and preventing the escape of oil or gas. This is essential during drilling, well testing, and other high-pressure operations.

Emergency Shut-In:

In the event of an unexpected pressure surge or kick, BOPs can swiftly shut in the well, isolating it from the surface and preventing the release of hydrocarbons.

Kick Control:

During drilling, the influx of formation fluids into the wellbore, known as a kick, can occur. BOPs help control and manage these kicks to ensure a safe drilling environment.

Role of BOPs in the Safety of Operations:

Preventing Blowouts:

The primary role of high-pressure BOPs is to prevent blowouts, which can lead to catastrophic environmental and safety consequences. By quickly sealing the wellbore, BOPs mitigate the risk of uncontrolled hydrocarbon releases.

Protecting Personnel:

BOPs provide a crucial safety barrier for personnel working on drilling rigs. In the event of a well control issue, the quick and effective operation of BOPs can prevent harm to the drilling crew.

Preserving the Environment:

Uncontrolled releases of oil and gas can have severe environmental impacts. BOPs act as a safeguard, minimizing the likelihood of spills and protecting ecosystems from the devastating effects of hydrocarbon pollution.

Meeting Regulatory Standards:

BOPs are a regulatory requirement in the oil and gas industry. Adherence to strict safety standards ensures that drilling operations are conducted responsibly and in compliance with environmental and industry regulations.

In the high-stakes world of oil and gas exploration, the Blowout Preventer stands as a critical guardian of safety. With its intricate components and advanced hydraulic systems, the BOP serves as the last defense against wellbore blowouts, protecting both human lives and the environment. As technology advances, the role of BOPs remains indispensable, ensuring that high-pressure drilling operations can proceed with the utmost safety and responsibility for humans, assets integrity and environment.

Comments

5 responses to “High-Pressure Operations – Understanding the Impressive Blowout Preventers (BOPs)”

Cool material👏.

I worked for over 20 years as a Comex Sat Diver and ROV Oceaneering MT Tech.

Thank you Philip, this much appreciated!

Sounds as a great and amazing career, well done, not many have this opportunity!

[…] bundles of tubes, hoses, and cables that transport various substances, such as hydraulic fluid, electrical power, and chemical injection fluids, between the surface and the seabed. These umbilicals are […]

Yep, all together 🙂